INTRODUCTION

Tribute Tanzania Limited was established on the 24Th of July 2013 to provide technical services in Industrial & Domestic Diesel Engine Generators, Motor Vehicles, Air Conditions, Lighting Towers, Water Pumps and Heavy Duty Equipment like Bull Dozers, Motor Graders, Soil Compactors, Excavators, Cranes and Wheel Loaders. Operational Office is based in Arusha Sakina Ward, Sakina Area along Nairobi Road Opposite Arusha Meat.

Due to high level of service required by our customers, we are continuously upgrading our staff quality through a number of professional courses and short courses, the staff compliment include an Engineer, Technicians and Artisans.

OUR VISION

Our Vision is to become the leading and most trusted Company in the Field of Generator and Heavy Duty Equipment Maintenance in the Region. We strive to achieve this by focusing individually on each project/Task and build a healthy and strong intimacy with our customers.

OUR MISSION.

At Tribute Tanzania Ltd, with Technical Proficiency and Expertise we cohesively provide sound business solutions through diagnosis/research, training and consultations to emerge as one among the best generators and heavy duty Equipment Maintenance Provider. This is the Commitments we are pride ourselves as an integrated team in responding timely to our customer requirements in fulfilling customer satisfaction. By keeping up to date with new product developments and the latest technology in generator and heavy duty Equipment Industry we can provide our current and future customers with complete Maintenance Technology solutions.

Below is the List of services offered by Tribute Tanzania Ltd;

– Service & Maintenance of Motor Vehicles Ranging from Saloon Cars, Pickups to 7 Tons Trucks

– Panel Beating & Spray Painting

– Generator Service and Maintenance – Dealing with Service and Maintenance of diesel engine generators ranging from 5KVA to 3000KVA, Supply and Installation of new Generators, Diesel Engine Overhaul, Supply generator Spare parts. Here we have qualified and experienced Technicians working under a qualified engineer with great experience in diesel engine generators.

– Carry genset size (Load Analysis) Estimate for buildings, Industries, Hotels, etc

– Sales of new and used generators …. Various sizes.

– Provide Technical Training for Generators-Service & Maintenance, Spare Parts, Engine, and Consumption Analysis.

– Service and Maintenance of Heavy Duty Equipment like Bull Dozers, Wheel Loaders, Motor Graders, Soil Compactors, Excavators, Cranes and Water Pumps.

– Electrical Installations both High Tension (HT) and Low Tension (LT).

– Domestic Installations, Electrical Repairs & Maintenance.

– Service and Maintenance of Air Conditions.

– Service & Maintenance of Water Pumps

– Aluminum Windows/ Works

– Laying of Steel Structures and Roofing

– Welding & Metal Fabrications including Window Grills & Gates, School Furniture, Beds etc.

COMPANY QUALITY ASSURANCE (QA) & QUALITY CONTROL (QC) POLICY.

Quality Assurance and Quality Control are very important and necessary to determine precision and accuracy, quality of the job. The essence is to create new values to meet customer expectations through the continuous improvement of consultancy, quality, quantity according to design and engineering in general through attention to its employees and the commitment to a sustainable growth pattern also encompassing the careful assessment of the activities and the development of innovative & efficient technologies.

QUALITY MANAGEMENT PLAN.

Each Maintenance Site/Job shall submit the QA/QC detailed the scope and tackles to attain the standards and meet beyond Customer/Client expectations. The following are some of the important guidelines:

– Project QC/QA Organization: Presents the organizations and key personnel involved in the Maintenance/Installation, their responsibilities & authorities. The structure of the QC/QA organization and the minimum training and experience of the maintenance Quality Assurance Officer & Personnel.

– Inspection & Verification Activities: Provides procedures for tracking maintenance/Installation inspection & verification activities for the contract, maintenance acceptance criteria and maintenance audits.

– Maintenance Deficiencies: Describes the procedures for tracking maintenance deficiencies from identification through acceptable corrective action.

– Documentation: Describes the procedures for the project documents that will be managed through a combination of a secure document filling & storage system and computerized document tracking system.

– Field Changes: Describes handling of quality plan changes to assure QC/QA objectives are met.

– Final Reporting: Describes the QC/QA documentation for the project.

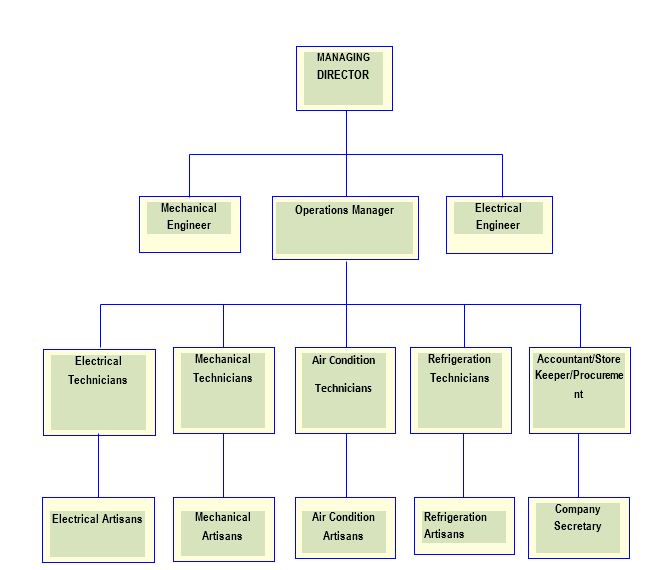

Our Organization Structure

Our Key Team Members

Engineer Matokeo Owden.

Director

BSC Mechanical Engineering • Member Engineers Registration Board –ERB • Member Institution of Engineers Tanzania-IE

Naike Mushi

Director

Fitter & Tunner.

Julius Matiko

Workshop Manager

2 Yrs working in Motor Vehicle, Plant Maintenances

Ally Ndee

Electrical Engineer

Over 10 Years generator experience.